Can An Impactor Crushing Equment Crush Granite

.jpg)

Experimental Study on Impact Crushing of Granite Particles

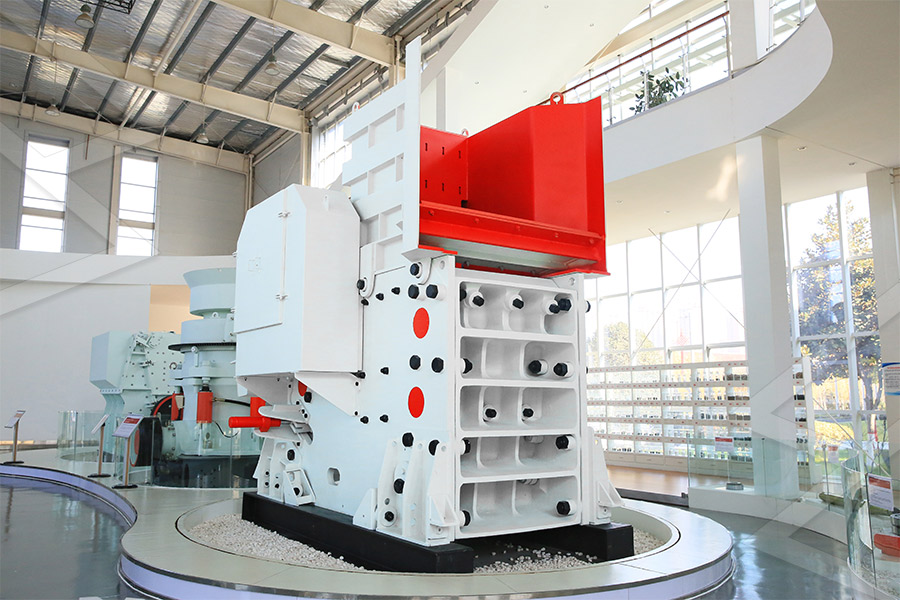

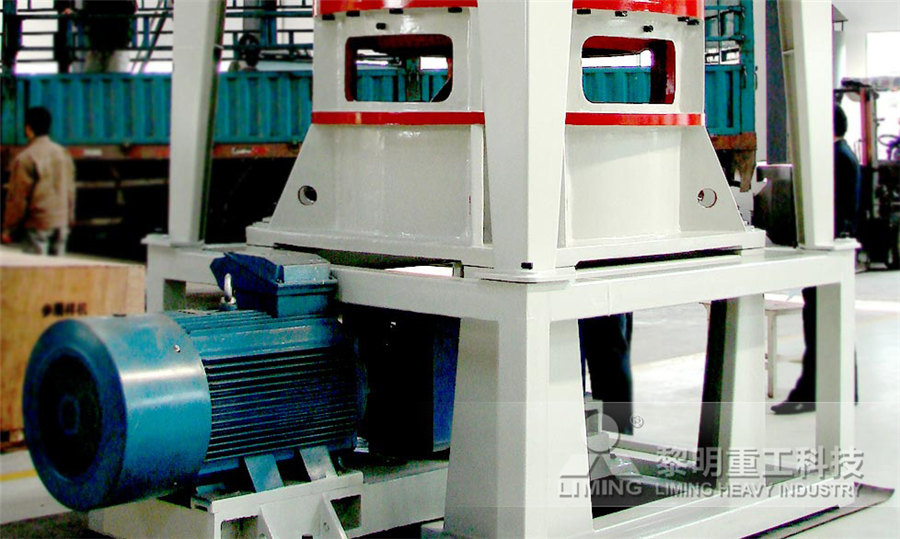

2018年11月1日 To study the specific influences of production parameters and structural parameters on a vertical shaft impact crusher (VSI), a pneumatic impact crushing device was designed and used to study the influence of different impact velocities, impact angles, and 2023年5月12日 The impact crusher has a large feeding port, a deep crushing cavity and a large crushing ratio, which can effectively complete the fine crushing of granite The gap between the impact plate and the hammer can be easily 6 Granite Crushers for Efficient Granite Rock 2023年2月23日 Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materials They are commonly used in mining, construction, and Understanding the Impact Crusher Working The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is Impact Crusher an overview ScienceDirect Topics

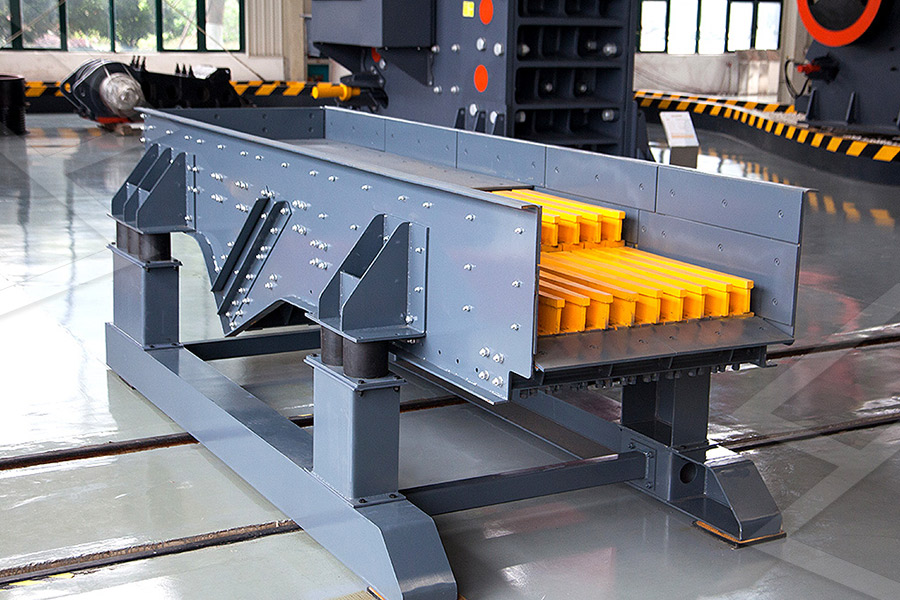

Impact crusher application and spare parts introduction

2024年3月4日 Aggregate Production:Impact crushers are extensively used in aggregate production for crushing materials like limestone, granite, and basalt Their high reduction ratios 2023年8月21日 An HSI crusher is suitable for crushing soft to mediumhard materials, such as limestone, gypsum, lignite, coal, coke, weathered shakes, and phosphate The horizontal shaft impactor is better suited for softer, less HSI Or VSI Impact Rock Crusher: Which Is Best 2015年4月1日 In emerging markets such as Russia, Africa, east Asia and South America among others, cone crushers are increasingly being replaced by impact crushers in granite and basalt quarries, providing an improvement in the Impact vs cone crushers: Which is more The allnew 700 series of Horizontal Shaft Sandvik impact crushers offers new levels of safety and efficiency Developed to comply with new EU legislation, you can configure these smart, modular crushers to operate in a variety of Stationary HSI Impact Crushers, Horizontal

How does an Impact Crusher work? RUBBLE

What are the benefits of an impact crusher? Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product A fast spinning rotor throws the material against a solid 2024年8月14日 Long life hammers, premium shafts and rotors, easily adjustable curtains, and wearresistant liners help maximize crushing productivity What’s Getting Crushed? Weighing Impact Rock Crushers: A Comprehensive OverviewThe main drawback to dolomite, though, is that its toughness causes crushing equipment to wear out faster Granite: Granite is an igneous rock that forms when lava crystallizes deep below the earth’s surface It’s another popular material for crushed stone in the US, accounting for as much as 15% of our crushed stone productionRock Crushing 101: A Beginner's Guide Senya Crushers2024年10月18日 Striking can be done with rapid moving hammers as seen on the Horizontal Shaft Impactor or being thrown against an anvil or rock wall as seen on the Vertical Shaft Impactor Impact crusher machines are available as What is an Impact Crusher? Zenith Crusher

HSI Or VSI Impact Rock Crusher: Which Is Best

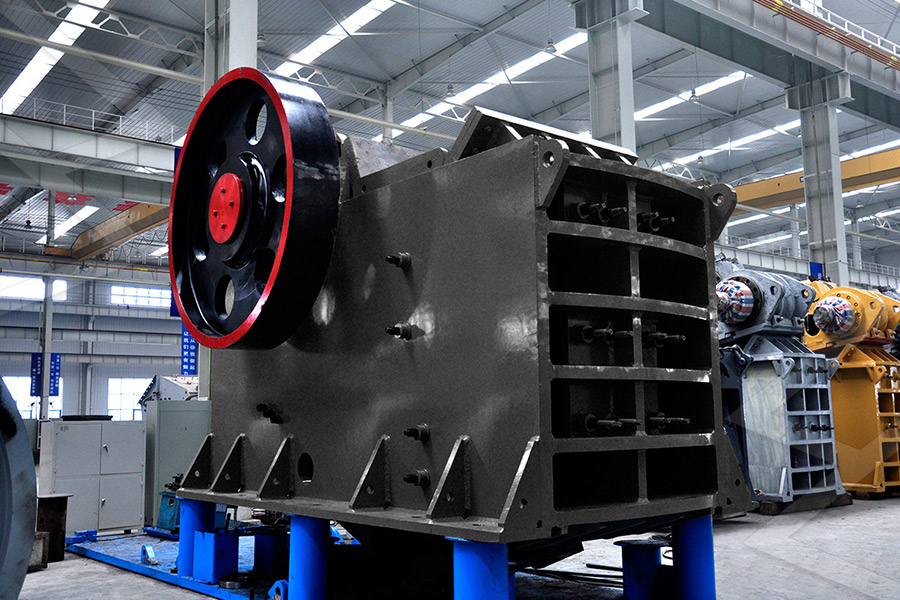

2023年8月21日 An HSI crusher is suitable for crushing soft to mediumhard materials, such as limestone, gypsum, lignite, coal, coke, weathered shakes, and phosphate The horizontal shaft impactor is better suited for softer, less 2023年2月21日 Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; Its primary function is to crush the materials that enter the crusher and prevent damage to other components The blow bar is responsible for delivering the impact The Ultimate Guide to Impact Crusher Blow Bars AGICO 2023年2月23日 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materialsThey are commonly used in mining, construction, and recycling industries to produce highquality cubical aggregates from various materials, including hard rock, soft rock, Understanding the Impact Crusher Working Principle for Efficient Crushing2023年6月3日 Stone crushing and quarrying activities have a significant impact on both human health and environmental quality The current study was carried out to evaluate the environmental impacts of Environmental Impact Assessment of a typical Stone Crushing

.jpg)

Crushing Can Experiment : Effect of Atmospheric Pressure

2020年12月3日 Air Pressure Can Crusher Experiment The pressure created in the air surrounding us plays an important role while doing this activity Objective: To crush the empty soda can and explore simple science concepts like air pressure, equilibrium, water vapor, condensation, and unbalanced forces Hypothesis: If water in a can heated to reach its boiling 2024年6月3日 The McCloskey I54v3 is a highperformance mobile impact crusher designed for versatility and efficiency It features a 48″ x 53″ fourbar impactor chamber with a 474″ x 333″ feed opening and a 530HP power unit Key Features: HighPerformance Impactor: Fourbar impactor chamber delivers high reduction ratios and excellent product shapeThe 9 Best Mobile Impact Crushers: Revolutionizing Crushing By prioritizing regular maintenance tasks like these, you can optimize your impact crusher’s performance while minimizing unexpected breakdowns or costly repairs in the long run Conclusion Conclusion The impact crusher is a versatile and efficient crushing machine that can revolutionize your operations Its unique working principle allows Impact Crusher working principle parts and maintenance2021年1月10日 Vertical shaft impactors are limited in the feed size they can process and are used as secondary or tertiary crushers only When a vertical shaft impactor operates, material is fed into the chamber from above the spinning rotor The material enters the rotors rapidly moving wings and is hurled outward to be broken upon the peripheral anvils or What Is an Impact Crusher and What Can It Do for You?

.jpg)

Portable Impactor Plants Eagle Crusher

4 天之前 An allelectric plant that provides high production crushing and screening on one chassis RapiDeploy 500 ®, is the industry’s firstever portable impactor plant with builtin, retractable conveyors that can crush, screen, Secondary or tertiary crushing in hard rock and gravels; Pebble crushing in mining circuits; Production of construction aggregate materials; Learn More About Rock Crushers With an array of different types, sizes, and purposes, choosing a rock crusher can quickly become overwhelming Add in the fact that a significant investment is required to Should I Choose an Impact Rock Crusher or Cone Crusher?2024年7月19日 Which equipment can be used for crushing rocks? The key to obtaining highquality crushed stone is choosing a stone crusher that matches the material characteristics With extensive industry experience and a deep How to Crush Stones: A Comprehensive Guide2024年10月18日 PF1010 Impact Crusher/Impactor for Limestone, Granite, Riverstone, Basalt, Glass Good Shape Aggregate Secondary Crushing, Find Details and Price about Impactor Impact Crusher from PF1010 Impact Crusher/Impactor for Limestone, Granite, Riverstone, Basalt, Glass Good Shape Aggregate Secondary Crushing Shanghai Kinglink Industry Co, LtdPF1010 Impact Crusher/Impactor for Limestone, Granite,

RM 120X Mobile Impactor Crush Different RUBBLE MASTER

The RM 120X impactor delivres a high reduction ratio while being easy to maintain The 4bar rotor is driven directly through a 400 HP John Deere diesel engine and can be used in primary and secondary crushing applications The crusher box features a 3stage singleapron impact wall for fast and easy adjustment of your closed side setting2023年3月11日 Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; An impact crusher is a machine used to crush materials by impact energy It works by feeding the material into a rotating rotor, which is equipped with a series of hammers As the rotor spins, the hammers strike the How Impact Crushers Work: A Comprehensive Guide AGICOOccationally, limestone can be very hard and difficult to crush Where most other mobile impact crushers fail RUBBLE MASTER's revolutionary mobile hard rock crusher can do the job The RM V550GO! is an impactor designed for difficult applications, so that you can reduce your machine investments and increase your profitsCrushing Limestone Impact Jaw Crushers RUBBLE 2024年7月17日 Primary crushing is the first stage of the stone crushing process At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers Jaw CrusherTypes of Crushers: Choosing the Right One for Each Stage

Rock Crusher with a High Reduction Ratio RUBBLE MASTER

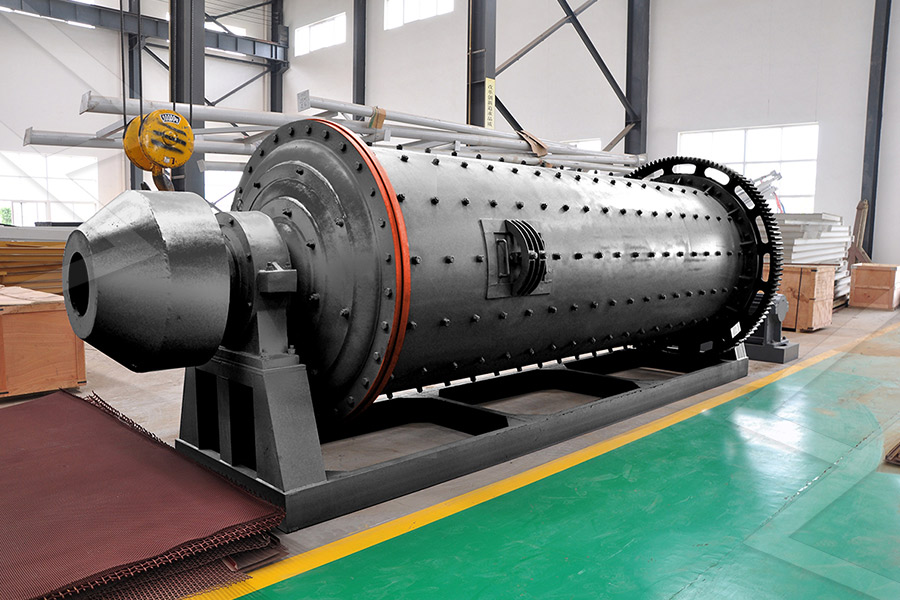

HardRock Impactor Crushing 10" Granite Crushing granite with a RM V550GO! impact crusher RM DemoShow with RM V550GO! + RM 90GO! + RM 100GO! When Should You Consider The RM V550GO! Over another Impact Crusher Without a doubt the RM V550GO! is a marvellous and special piece of machinery Based on the RUBBLE MASTER mobile impact Vertical Shaft Impactor (VSI) is a type of crusher that is used to reduce the size of rocks and other materials to create aggregates and other construction materials VSI is a machine that uses velocity to crush rocks into smaller sizes VSI Stands for Vertical Shaft Impactor The material to be crushed is fed into the center of the rotor Vertical Shaft Impactor Maxwell CrushtechStone crushing and quarrying activities have a significant impact on both human health and environmental quality The current study was carried out to evaluate the environmental impacts of Environmental Impact Assessment of a typical Stone The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered Can an impactor crusher crush granite ireland granite jaw crusher if you want a granite crusher with big feeding size and long service life the jaw Can An Impactor Crusher Crush Granite

.jpg)

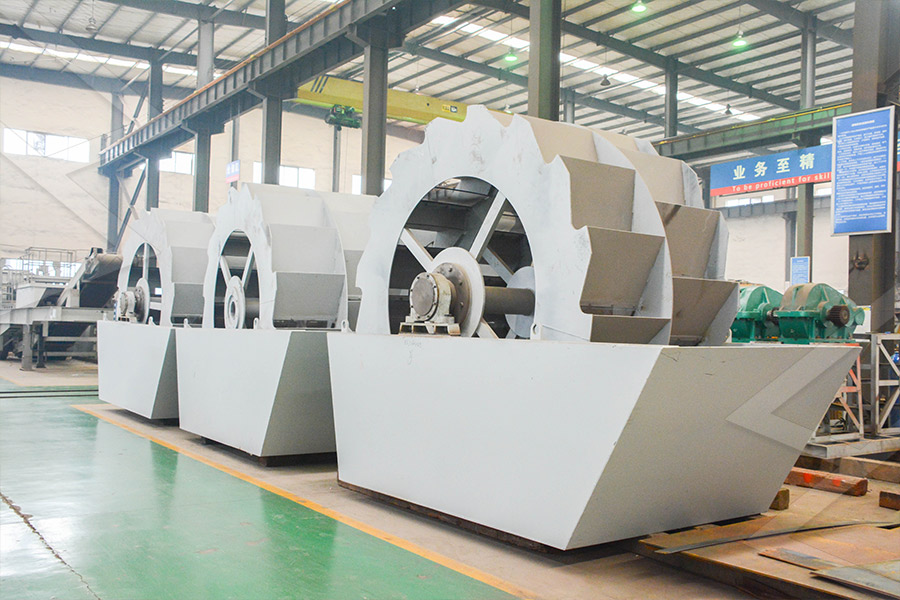

Types of Rock Crushers Quarry Crushing

5 天之前 Impact rock crushers can also require frequent part changes and can create a large amount of dust that can be an issue on some worksites Portable vs Stationary Crushing Plants Depending on the length of your project and 2016年4月7日 Fine (tertiary) crushing – In this crushing stage, the quality and quantity of fine products are determined Quality requirements can be stringent for the final products, especially within the quarrying industry Customer requirements common to both the aggregate and mining industries are capacities and quality (fraction/particle size)Selecting the right type of crushing equipment Quarry2024年4月19日 The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stageTypes of Crushers Explained: Everything You Need to Know2012年10月14日 Explain the “crushing can” demo by using gas laws Okereke Faith on June 05, 2019: Which principle is applicable to the can crush experiment Teresa Coppens (author) from Ontario, Canada on November 24, 2012: So true UnnamedHarald My son loved performing this demo with me We did it many times to get the video made and it amazed us every timeThe Crushing Can Demonstration: Physics of Atmospheric Pressure

.jpg)

AusIMM – Leading the way for people in resources

%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY 2024年10月10日 Concluding Insights on Crushing Stone Effectively Crushing stone efficiently requires a welldesigned process and the right combination of crushing equipment and screeners By understanding the options available and their specific uses, operators can ensure that crushed stone meets project requirements while minimizing waste and improving The Ultimate Guide on How to Crush Stone: Techniques and 4 天之前 Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from 1) First, arrange the crafter as follows Note that direction of the arrows (black lines) It is critical that these are in the right direction or it may not work Use the wrench to rotate them as needed The central Crushing Wheel Create Wiki

.jpg)

Rock Crushing 101: A Beginner's Guide Senya Crushers

The main drawback to dolomite, though, is that its toughness causes crushing equipment to wear out faster Granite: Granite is an igneous rock that forms when lava crystallizes deep below the earth’s surface It’s another popular material for crushed stone in the US, accounting for as much as 15% of our crushed stone production2024年10月18日 Striking can be done with rapid moving hammers as seen on the Horizontal Shaft Impactor or being thrown against an anvil or rock wall as seen on the Vertical Shaft Impactor Impact crusher machines are available as What is an Impact Crusher? Zenith Crusher2023年8月21日 An HSI crusher is suitable for crushing soft to mediumhard materials, such as limestone, gypsum, lignite, coal, coke, weathered shakes, and phosphate The horizontal shaft impactor is better suited for softer, less HSI Or VSI Impact Rock Crusher: Which Is Best 2023年2月21日 Granite Crushing Plant; Projects Menu Toggle 500t/h Coal Gangue Mobile Crushing Plant; 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; Its primary function is to crush the materials that enter the crusher and prevent damage to other components The blow bar is responsible for delivering the impact The Ultimate Guide to Impact Crusher Blow Bars AGICO

Understanding the Impact Crusher Working Principle for Efficient Crushing

2023年2月23日 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materialsThey are commonly used in mining, construction, and recycling industries to produce highquality cubical aggregates from various materials, including hard rock, soft rock, 2023年6月3日 Stone crushing and quarrying activities have a significant impact on both human health and environmental quality The current study was carried out to evaluate the environmental impacts of Environmental Impact Assessment of a typical Stone Crushing 2020年12月3日 Air Pressure Can Crusher Experiment The pressure created in the air surrounding us plays an important role while doing this activity Objective: To crush the empty soda can and explore simple science concepts like air pressure, equilibrium, water vapor, condensation, and unbalanced forces Hypothesis: If water in a can heated to reach its boiling Crushing Can Experiment : Effect of Atmospheric Pressure2024年6月3日 The McCloskey I54v3 is a highperformance mobile impact crusher designed for versatility and efficiency It features a 48″ x 53″ fourbar impactor chamber with a 474″ x 333″ feed opening and a 530HP power unit Key Features: HighPerformance Impactor: Fourbar impactor chamber delivers high reduction ratios and excellent product shapeThe 9 Best Mobile Impact Crushers: Revolutionizing Crushing

Impact Crusher working principle parts and maintenance

By prioritizing regular maintenance tasks like these, you can optimize your impact crusher’s performance while minimizing unexpected breakdowns or costly repairs in the long run Conclusion Conclusion The impact crusher is a versatile and efficient crushing machine that can revolutionize your operations Its unique working principle allows 2021年1月10日 Vertical shaft impactors are limited in the feed size they can process and are used as secondary or tertiary crushers only When a vertical shaft impactor operates, material is fed into the chamber from above the spinning rotor The material enters the rotors rapidly moving wings and is hurled outward to be broken upon the peripheral anvils or What Is an Impact Crusher and What Can It Do for You?