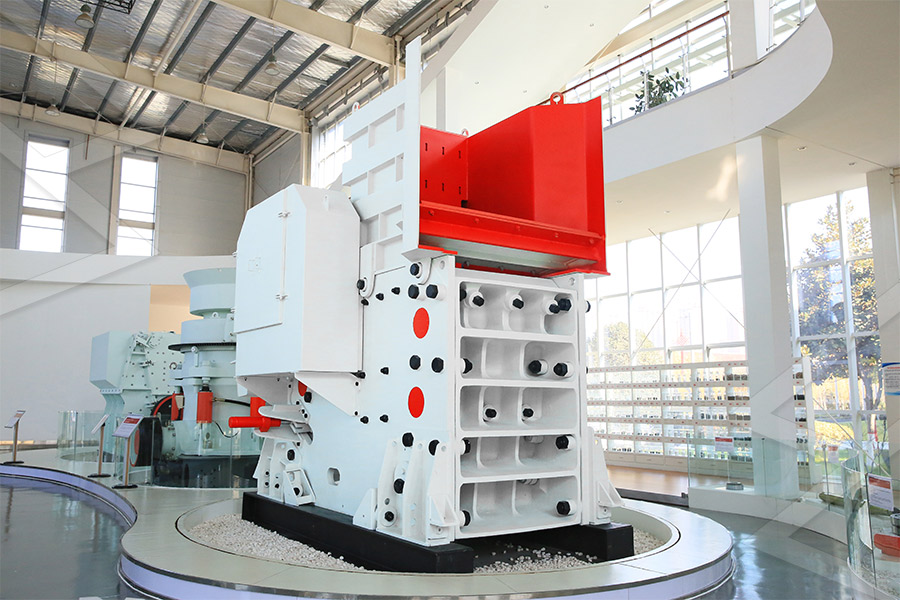

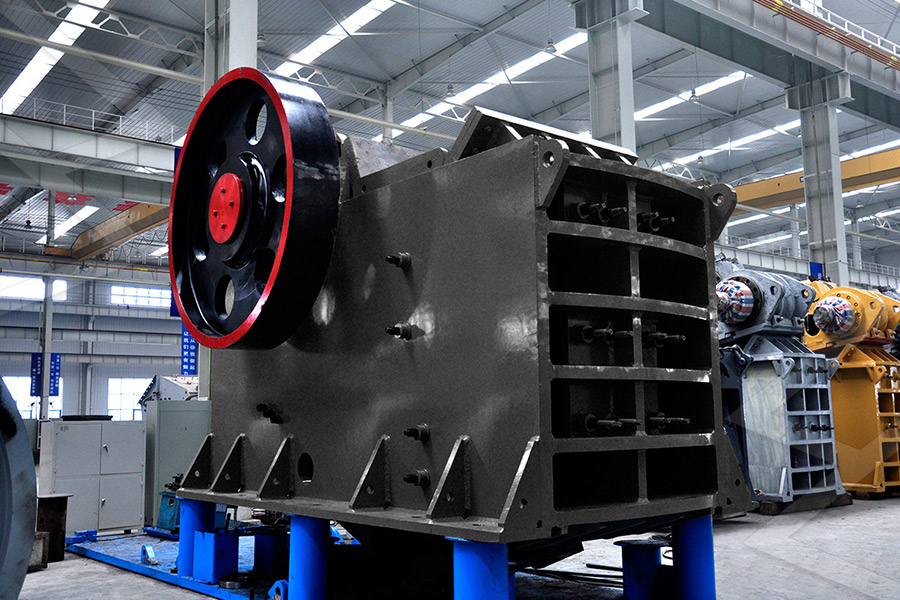

Widely Used Stone Fine Impact Mining Mill In Mining Industry

Stone Mining Industry: Overview and Applications of Stones

2024年9月25日 Stone mining, a vital sector in the global extractive industry, plays a crucial role in meeting the growing demand for construction materials, infrastructure development and various industrial applications The chapter deals with the dynamic realm of the stone mining2024年9月26日 Stone mining, a vital sector in the global extractive industry, plays a crucial role in meeting the growing demand for construction materials, infrastructure development and Stone Mining Industry: Overview and Applications of 2022年10月4日 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described The main factors influencing rock fragmentation by Reduction of Fragment Size from Mining to Mineral 2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material

Review on advances in mineral processing technologies

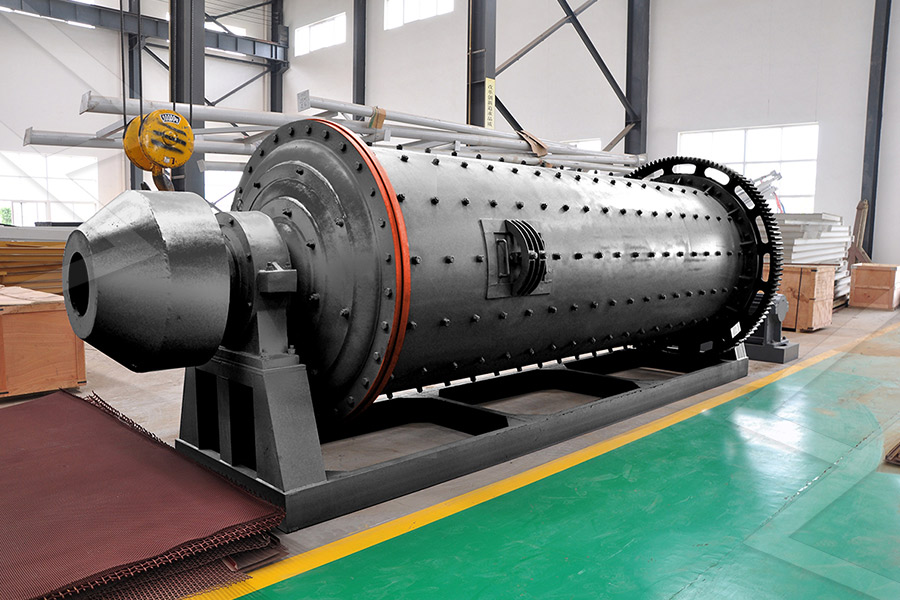

2022年4月1日 Mine wastes are generated during open pit and underground mining activities and include waste rock, overburden, and mining waters Mineral processing wastes are generated Introduction: The mine ball mill, an integral component of the mining industry, plays a pivotal role in the processing of ores and minerals China, known for its vast mineral resources and The Mine Ball Mill: A Cornerstone of China’s Mining Industry2003年1月1日 Due to higher energy efficiency and the ability to produce the extremely fine size of the product, stirred media mills are frequently used to grind fine or ultrafine particles in many(PDF) FINE GRINDING IN THE AUSTRALIAN 2024年10月13日 Grinding mills are crucial equipment in the mining and mineral processing industry, used primarily for the reduction of ore and mineral particles The proper functioning of Understanding the operation of grinding mills in the mining

.jpg)

Stirred media mills in the mining industry: Material

2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional 2020年5月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional Stirred media mills in the mining industry: Material 2024年9月25日 As per estimates, in 2022, the estimated market for stone mining and quarrying was worth US$ 55069 million and is expected to grow at a compound annual growth rate (CAGR) of 35% to reach US$ 70076 million by 2029 Limestone is a crucial industrial mineral widely used in various sectors, including construction, cement manufacturing, and Stone Mining Industry: Overview and Applications of StonesBond’s work index is an innovative concept now widely used in the industry to size crushers and grinding mills since the publication of Fred Bond’s approach in 1952 The work index is a comminution parameter that expresses the Physical Processing: Innovations in Mineral

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

2024年9月20日 The term Mine to Mill (M2M) is now widely used within the mining industry However, widespread usage does not necessarily equate to a clear understanding of the concept The purpose of this booklet is to examine the elements which together make up M2M and in doing so: >> Provide an understanding of the concept and its applications2023年5月11日 Quarrying The process of extracting stone, building materials, or other resources from a quarry, an openpit mine typically used for mining stone or other materials used in construction Quartz A mineral composed of silicon dioxide (SiO2), a principal component of igneous rocks and sedimentary rocks like sandstone and shale, and is also the 2024 Mining Terms Explained An Underground MinerBall mill grinding machines are widely used in various industries for the comminution of materials into fine powders They are versatile tools that offer efficient and reliable grinding and mixing capabilities Mining and Ore Processing: Ball mills are used for grinding ores and minerals, enabling the extraction of valuable metals Ball Mill Grinding Machines: Working Principle, Types, Parts New technologies can benefit the mining industry and consumers in all stages of this life cycle Current ultrafine grinding by vertical stirred mills has very high energy requirements (Gao et al, 1995; Orumwense and Forssberg, 1992) This method is widely used for coal and to remove shale from construction aggregates Early work has Evolutionary and Revolutionary Technologies for Mining

Global Mine Report 2023: PwC

2023年6月22日 The mining industry needs skilled employees and faces an existential talent shortage, but to attract talent it must change perceptions about the industry In a survey by the Mining Industry Human Resources Council (MiHR) of Canada, a majority of Canadians aged 15 to 30 said they would definitely or probably not consider a career in mining The 2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient operating conditionsStirred media mills in the mining industry: Material 2003年1月1日 The making of a stirred media mill is of the types according to the stirrer geometry and mill chamber, which are as follows (also shown in Figure 7) [43], I Disc stirrer Stirred Media Mill II (PDF) FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY 2020年6月1日 Ball mills have traditionally been used for fine grinding of minerals, and in these cases smaller ball sizes than in conventional grinding are used to increase contact area and decrease collision intensity [15], and lower mill speeds are used to cause the media to cascade rather than cataract, shifting the typical forces experienced from impact Stirred media mills in the mining industry: Material

.jpg)

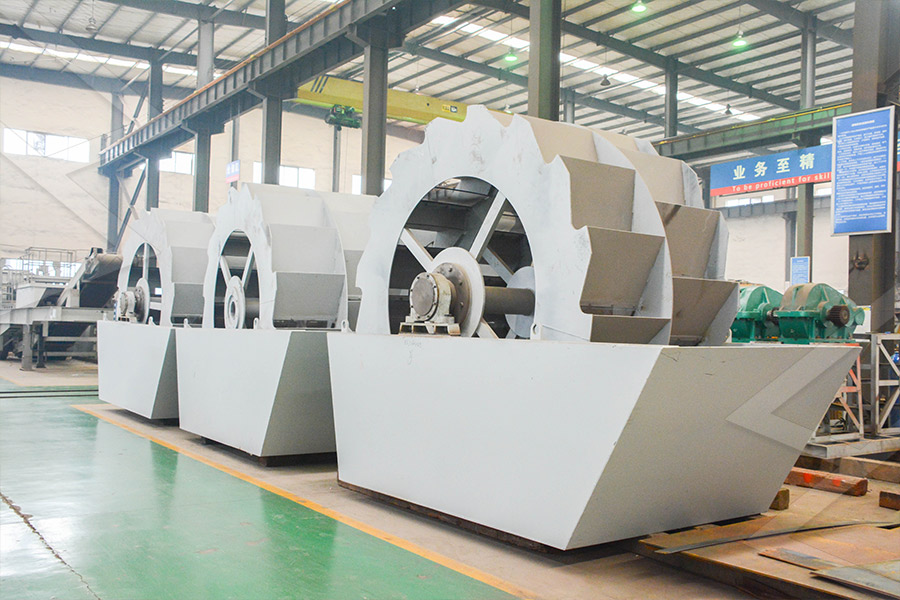

The Life Cycle of Water Used in Flotation: a Review Mining

2018年9月27日 Due to the limitation of freshwater sources and increasingly stringent disposal standards [13, 74, 79], the minerals industry has attempted to increase water use efficiency, reduce freshwater utilization, and minimize water discharge, or seek alternatives to fresh water [57, 59, 78, 84, 101]It is widely accepted that flotation is the most popular mineral processing 2021年9月24日 Markettrendbased strategies for the stone mining and quarrying market include popularity of precision surface excavation machines in mining, robotic in stone mining, cognitive computing will Stone Mining and Quarrying Global Market 2023年10月4日 Mining balls, in various forms such as grinding balls, steel grinding balls, forged steel grinding balls, and rolled grinding balls, are indispensable components in the mining industryThese durable and precisely Mining Balls: The Backbone of Material Processing2023年3月15日 Ball Mills: These cylindrical mills use steel balls or rods as grinding media and are often employed in the mining industry for grinding ores into fine powders Hammer Mills: Commonly used in food processing and agricultural industries, hammer mills use hammers attached to a spinning rotor to crush and grind materials into smaller particlesThe Evolution and Importance of Grinding Mills in Modern Industry

.jpg)

How Autonomous Drones in Mining are Revolutionizing the Industry

2023年3月13日 Successful Case Studies of Autonomous Drones in Mining Industry A Rio Tinto's Mine of the Future Program Christopher highlights how Rio Tinto's Mine of the Future program is a successful example of utilizing technology to improve safety, productivity, and costeffectiveness Launched in 2008, the program uses autonomous technologies China Mine Impact Mill wholesale Select 2024 high quality Mine Impact Mill products in best price from certified Chinese Mine manufacturers, Steel Mill suppliers, wholesalers and factory on MadeinChina Mineral Industry, Stone Industry Drive: Electromagnetic Crushing Style: Grinding Impact 1 / 6 Favorites Ultrafine Powder China Mine Impact Mill, Mine Impact Mill Wholesale, 2022年3月24日 Likewise, as a leading industry in raw material production, the mining industry is trying to take advantage of these systems in its different stages, from exploration to mineral processing(PDF) Renewable Energy Systems in the Mining Industry: A 2019年8月29日 Sensor‐based ore sorting can be used as a separation process for coarser grain sizes before the application of fine comminution and separation technologies and is applicable for a large variety (PDF) Sensor‐Based Ore Sorting Technology in Mining

Review on advances in mineral processing technologies

2022年4月1日 Comminution methods that rely more on attrition rather than mechanical impact have an effect of abrading Commercial stirred mills used to process fine to ultrafine particles NapierMunn et al, 1996), of which, hydrocyclones and screens are the most widely adopted in the mining industry Hydrocyclones use centrifugal forces Finding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector The list includes suppliers of crushers, rock breaker Mining Crushers, Breakers Grinding Mills for the Mining industryThe India stone mining and quarrying market has been witnessing significant growth due to the increasing demand for stones used in construction, road building, and landscaping Stones such as granite, marble, limestone, and sandstone are widely extracted from mines and quarries to cater to the construction industry`s needsIndia Stone Mining And Quarrying Market (20242030)2021年10月28日 The diffusion of Industry 40 technologies in the mining sector (Mining 40) can prevent a technological shock if they are implemented in all segments, including quarrying (Surface Mining 40)Digital Transformation in the Mining Sector:

Mining Industry Insights: Guide to Processes

2024年10月15日 Mining Industry: A Complete Guide The mining industry involves the discovery and extraction of naturally occurring minerals from the earth Since the beginning of civilization, clay, stones, and metals found close 2012年11月14日 10% in minetomill activities • Reduces greenhouse emissions by reducing use of explosives Applications in Our Nation’s Industry The aggregates industry, representing the largest segment of the US mining industry, will benefit the most from minetomill technology, focusing on particle size control rather than particle size reductionITP Mining: MinetoMill Optimization Energygov2018年8月17日 Ball Mills — these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder Ball mills use a feed of about 15 mm (½ in) or finer and Grinding Mills — Types, Working Principle Applications2024年2月28日 Mining Market Outlook 2032 The global mining market size was USD 213653 Billion in 2023 and is likely to reach USD 367138 Billion by 2032, expanding at a CAGR of 62% during 2024–2032The market growth is attributed to the growing inclination toward electric vehicles and increasing urbanization around the world Increasing urbanization around the Mining Market Size, Share, Growth Industry Trends [2032]

.jpg)

129: Mining Geosciences LibreTexts

The nature of mining processes creates a potential negative impact on the environment both during the mining operations and for years after the mine is closed This impact has led most of the world’s nations to adopt regulations designed to moderate the negative effects of mining operations people have used stone, ceramics and, later 2021年9月30日 Raymond mill is one of the widely used equipment in grinding industry According to industry statistics, the market share of Raymond mill in China is as high as more than 70% It is a common equipment for grinding materials in mine industry 2 Different applicable materials Raymond mill has been widely used in highfine pulverization Raymond Mill for Mining and Mineral Processing2024年10月19日 Xingaonai Group provides highquality crushers, jaw crushers, cone crushers, mobile crushers, sand making machines and other main products, with supporting equipment such as feeders, belt conveyors, powder concentrators, etcCone CrusherJaw CrusherStone CrusherXingaonai Heavy 2012年11月14日 611 Structure of the Mining Industry Mining Industry Segments Mining in one form or another has existed since ancient times The modern industry has evolved by incorporating gradual improve ments into common practice Mining in the United States can be classified in several ways The classification used in this chapter recog nizes four ITP Mining: Water Use in Industries of the Future: Mining

.jpg)

Stone Mining Industry: Overview and Applications of Stones

2024年9月25日 As per estimates, in 2022, the estimated market for stone mining and quarrying was worth US$ 55069 million and is expected to grow at a compound annual growth rate (CAGR) of 35% to reach US$ 70076 million by 2029 Limestone is a crucial industrial mineral widely used in various sectors, including construction, cement manufacturing, and Bond’s work index is an innovative concept now widely used in the industry to size crushers and grinding mills since the publication of Fred Bond’s approach in 1952 The work index is a comminution parameter that expresses the Physical Processing: Innovations in Mineral 2024年9月20日 The term Mine to Mill (M2M) is now widely used within the mining industry However, widespread usage does not necessarily equate to a clear understanding of the concept The purpose of this booklet is to examine the elements which together make up M2M and in doing so: >> Provide an understanding of the concept and its applicationsUNDErsTaNDINg MINE TO MILL 911 Metallurgist2023年5月11日 Quarrying The process of extracting stone, building materials, or other resources from a quarry, an openpit mine typically used for mining stone or other materials used in construction Quartz A mineral composed of silicon dioxide (SiO2), a principal component of igneous rocks and sedimentary rocks like sandstone and shale, and is also the 2024 Mining Terms Explained An Underground Miner

.jpg)

Ball Mill Grinding Machines: Working Principle, Types, Parts

Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders They are versatile tools that offer efficient and reliable grinding and mixing capabilities Mining and Ore Processing: Ball mills are used for grinding ores and minerals, enabling the extraction of valuable metals New technologies can benefit the mining industry and consumers in all stages of this life cycle Current ultrafine grinding by vertical stirred mills has very high energy requirements (Gao et al, 1995; Orumwense and Forssberg, 1992) This method is widely used for coal and to remove shale from construction aggregates Early work has Evolutionary and Revolutionary Technologies for Mining2023年6月22日 The mining industry needs skilled employees and faces an existential talent shortage, but to attract talent it must change perceptions about the industry In a survey by the Mining Industry Human Resources Council (MiHR) of Canada, a majority of Canadians aged 15 to 30 said they would definitely or probably not consider a career in mining The Global Mine Report 2023: PwC2020年6月1日 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient operating conditionsStirred media mills in the mining industry: Material

.jpg)

(PDF) FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY

2003年1月1日 The making of a stirred media mill is of the types according to the stirrer geometry and mill chamber, which are as follows (also shown in Figure 7) [43], I Disc stirrer Stirred Media Mill II 2020年6月1日 Ball mills have traditionally been used for fine grinding of minerals, and in these cases smaller ball sizes than in conventional grinding are used to increase contact area and decrease collision intensity [15], and lower mill speeds are used to cause the media to cascade rather than cataract, shifting the typical forces experienced from impact Stirred media mills in the mining industry: Material